The Armoloy process

The solution and application process are carefully monitored to produce a very thin, dense chromium coating. Armoloy TDC coated parts reduce friction, increase wear life and enhance corrosion resistance.

Armoloy TDC provides corrosion resistance equivalent to 440C stainless steel.

The coating’s micro-nodular surface finish will provide a coefficient of friction as low as .12

Increases surface hardness up to 78Rc increasing cycle time and wear life.

With increased surface hardness & reduced friction, the coating gives anti-galling properties to threaded components.

How we help

Armoloy is a proprietary process that has been in the UK since 1989. Since that time Armoloy has been used and specified by some of the leading companies in their respective fields.

The many benefits of Armoloy have been proven invaluable in thousands of applications.

Ask the experts

We believe that recommendation is the highest achievement we can aim to accomplish from our clients.

To see such a huge proportion of those, we surveyed stating they’re highly likely to recommend us is a wonderful support of our services.

ArmoSpeed is a premium service to help you meet urgent requirements

Industry solutions

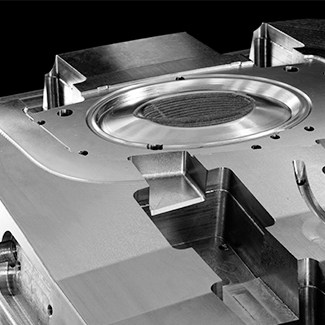

Precision, Quality, Durability, we aim to add value across the spectrum of manufacturing applications. Whether it be one part or a million parts, whether for the Aerospace Industry, Oil & Gas, Nuclear, Defence, the tools of Plastic Injection moulding, Automated Machinery or Linear Motion the Armoloy process takes manufacturing technology and makes it better.

Armoloy TDC coating is widely used throughout the Power sector reducing costs in a variety of areas.

Accurate, high load and low friction products for the aerospace industry.

Armoloy TDC reduces maintenance requirements and downtime by extending the life of your mould and die's.

Highly accurate solutions for the Oil & Gas Industry.

Products for the food industry.

Bearing Applications allows the use of metals that are less expensive, easier to machine, more resistant to fatigue, and longer-lived.

Armoloy TDC can significantly improve the performance of Food Processing Machinery and reduce downtime.

For protection against the most common forms of wear including corrosive, abrasive, and erosive wear.